Supply and start-up of the first press for pomace squeezing

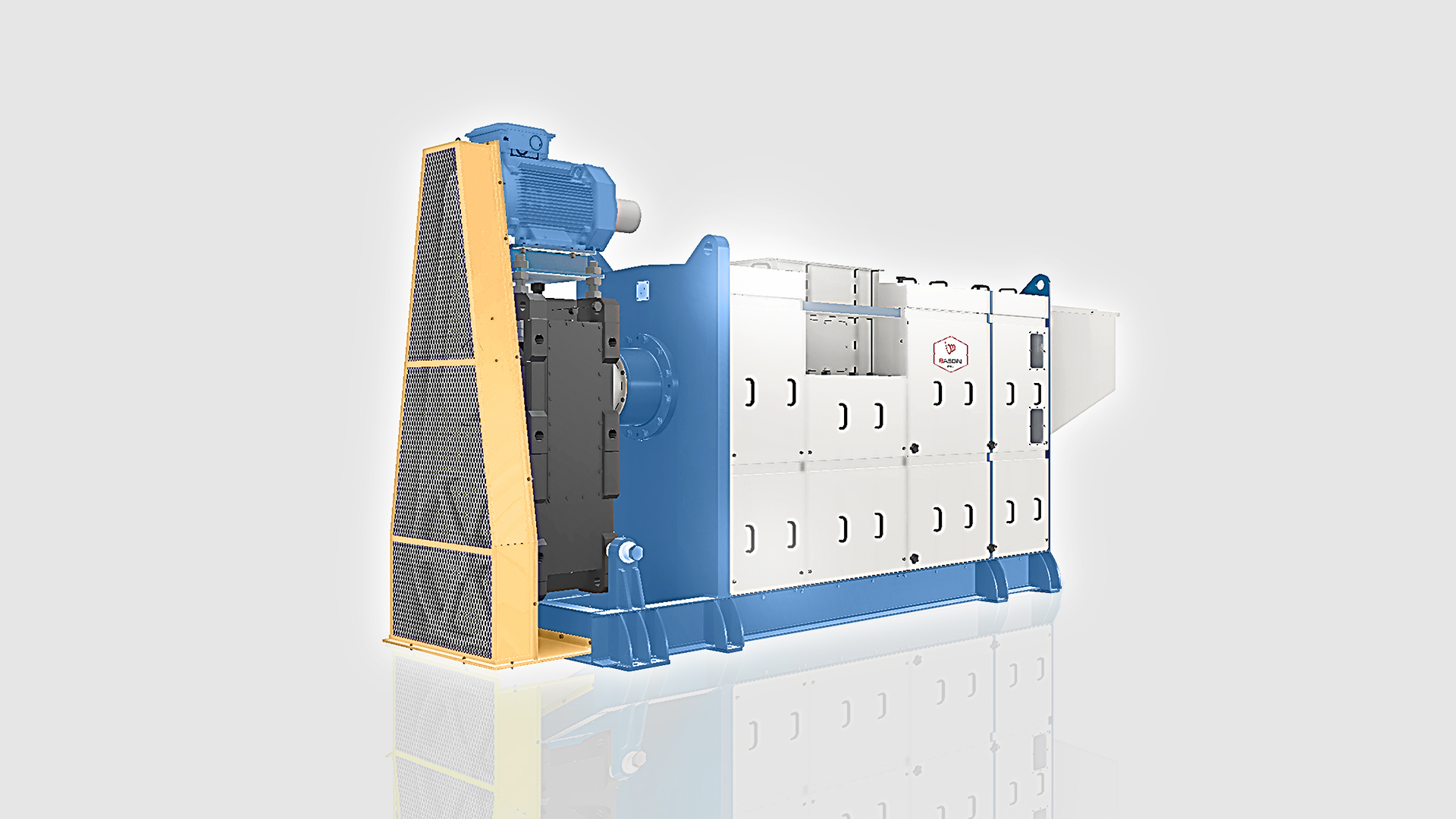

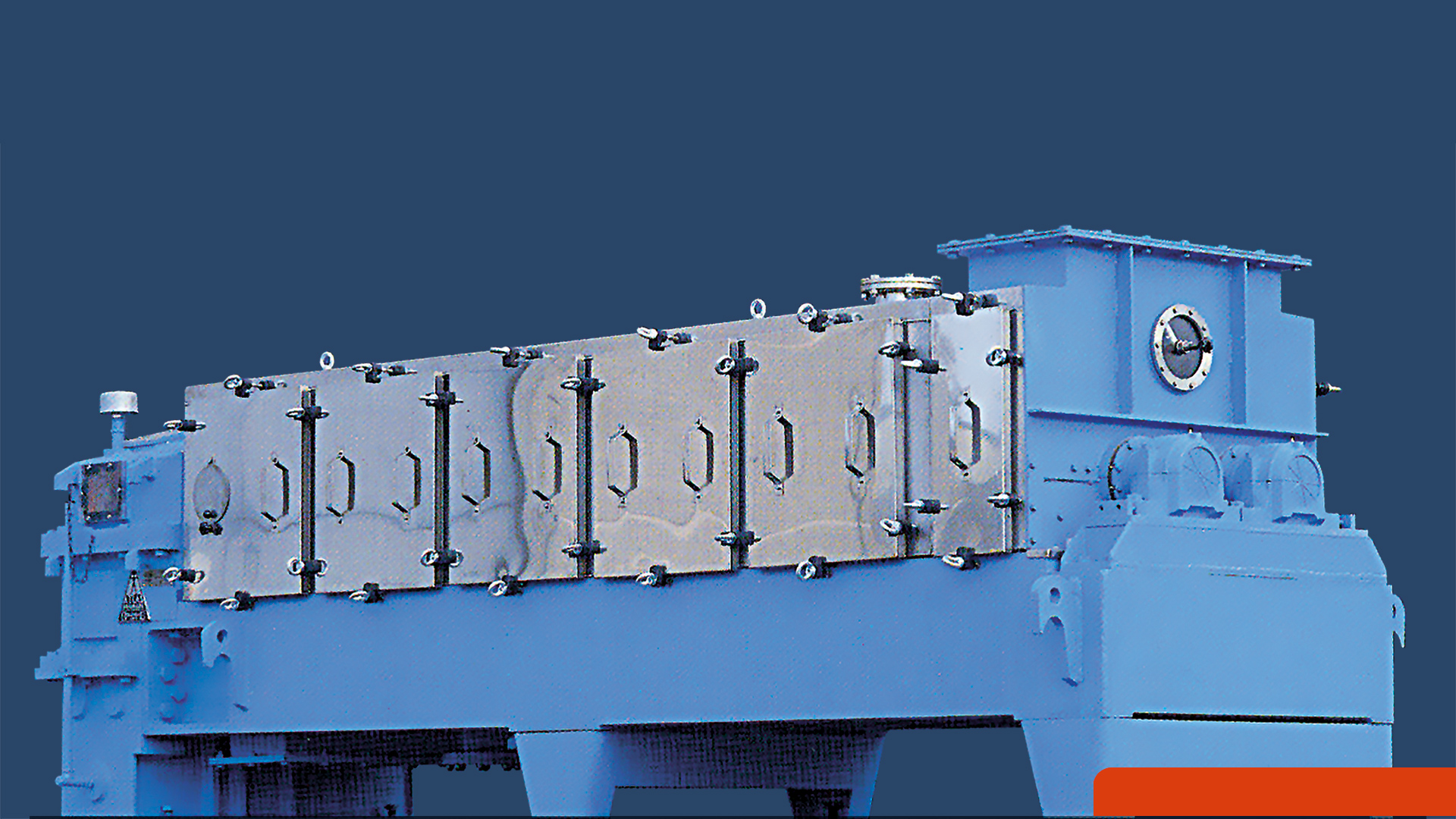

In July 2017 the first Babbini double screw press for marc squeezing (see photo) was started up. Following several successful tests of marc pressing by means of pilot presses, it was possible to get the necessary indications to size the industrial scale press and to define the necessary modifications to squeeze this particular type of product.  Historically, marc is mechanically dewatered using single screw oenological presses delivering a pressed product having a final dry substance equal to 36-42%. With the new Babbini double screw presses it is possible to increase the final dry substance content in marc up to 41-45% depending on the product, with peaks higher than 50%. The press is equipped with uprated gearbox, manufactured by GPS Engineering, allowing to achieve the high internal pressures and the high absorptions needed to press marc. The double screw Babbini presses, suitably sized and modified on the basis of the characteristics of the different products, prove to be suitable for pressing other by-products or agro-industrial products in addition to sugar beet pulp, fish and rendering (meat meal).

Historically, marc is mechanically dewatered using single screw oenological presses delivering a pressed product having a final dry substance equal to 36-42%. With the new Babbini double screw presses it is possible to increase the final dry substance content in marc up to 41-45% depending on the product, with peaks higher than 50%. The press is equipped with uprated gearbox, manufactured by GPS Engineering, allowing to achieve the high internal pressures and the high absorptions needed to press marc. The double screw Babbini presses, suitably sized and modified on the basis of the characteristics of the different products, prove to be suitable for pressing other by-products or agro-industrial products in addition to sugar beet pulp, fish and rendering (meat meal).