The industrialisation process has started

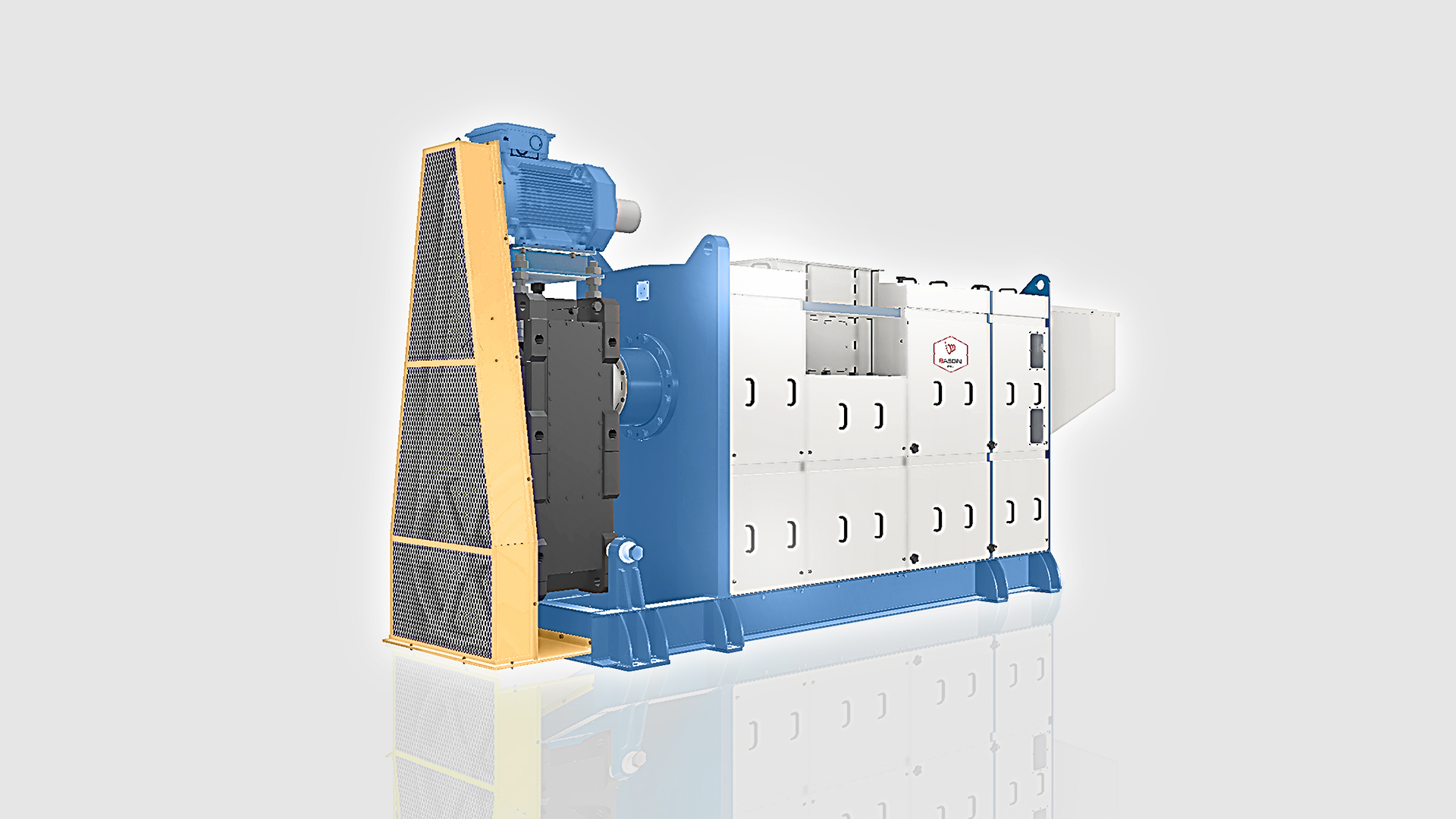

PB50V-A – After the positive test of the PB50V prototype at Südzucker Sugar Factory in Ochsenfurt, the press is now in an advanced industrialisation phase. The basic project was in fact updated in its critical or improvable points. We intervened in particular on the following points:

• Reliability

• Reliability

The most stressed and critical points were substantially modified..

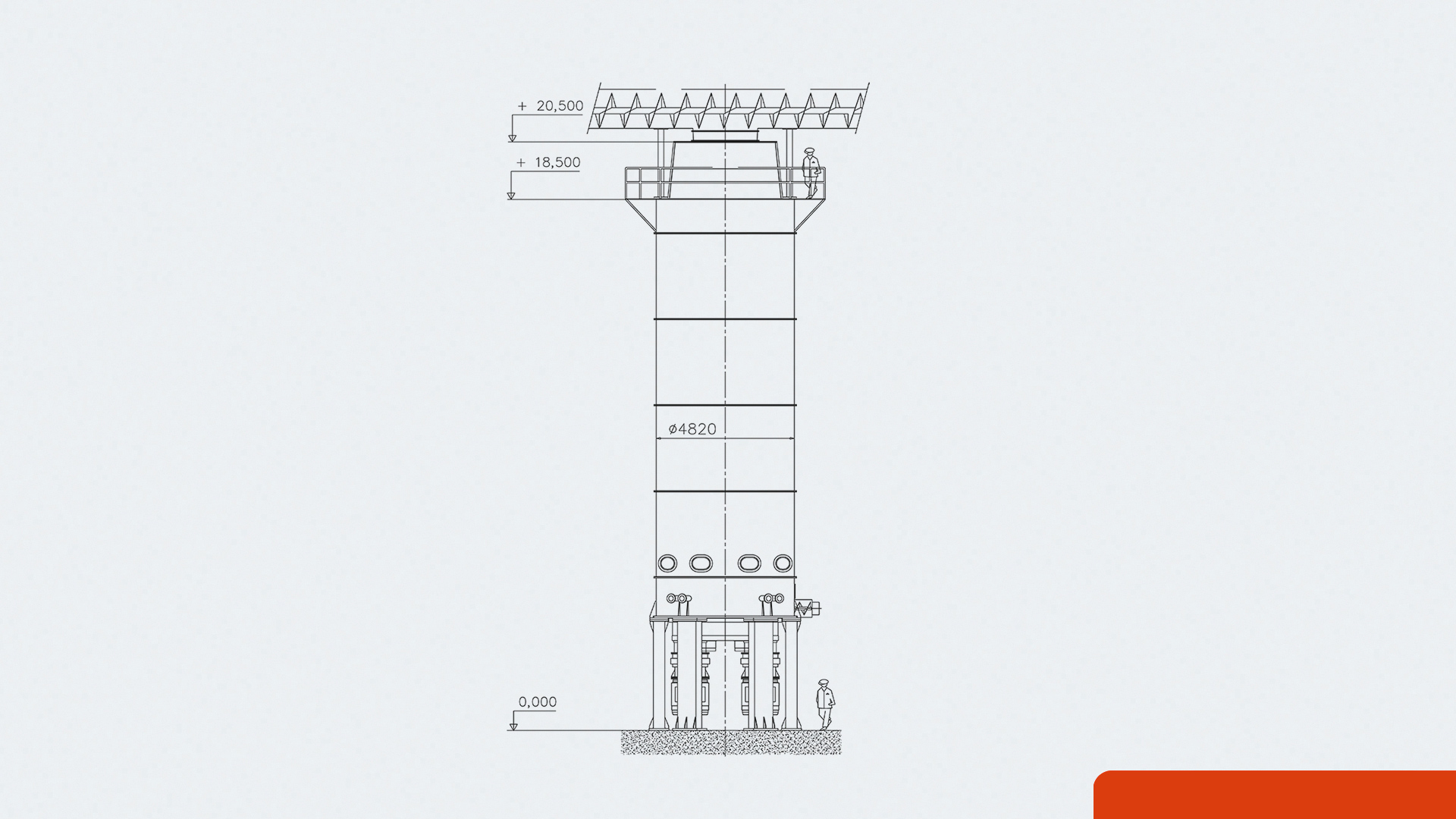

• Fast erection

We reduced the total number of elements and we simplified their connection

• Easiest access

It is possible to inspect the inside of the press without disassembling the elements.

• Maintenance simplicity

It is possible to intervene and to operate easily both at the outlet and at the inlet; moreover it will be easier to inspect spindles, plates and gearbox.

• Control devices installation

We are now studying both a monitoring device for the bearings on the drive opposite side and a control device for the filtering plates to check the spindles deformation.

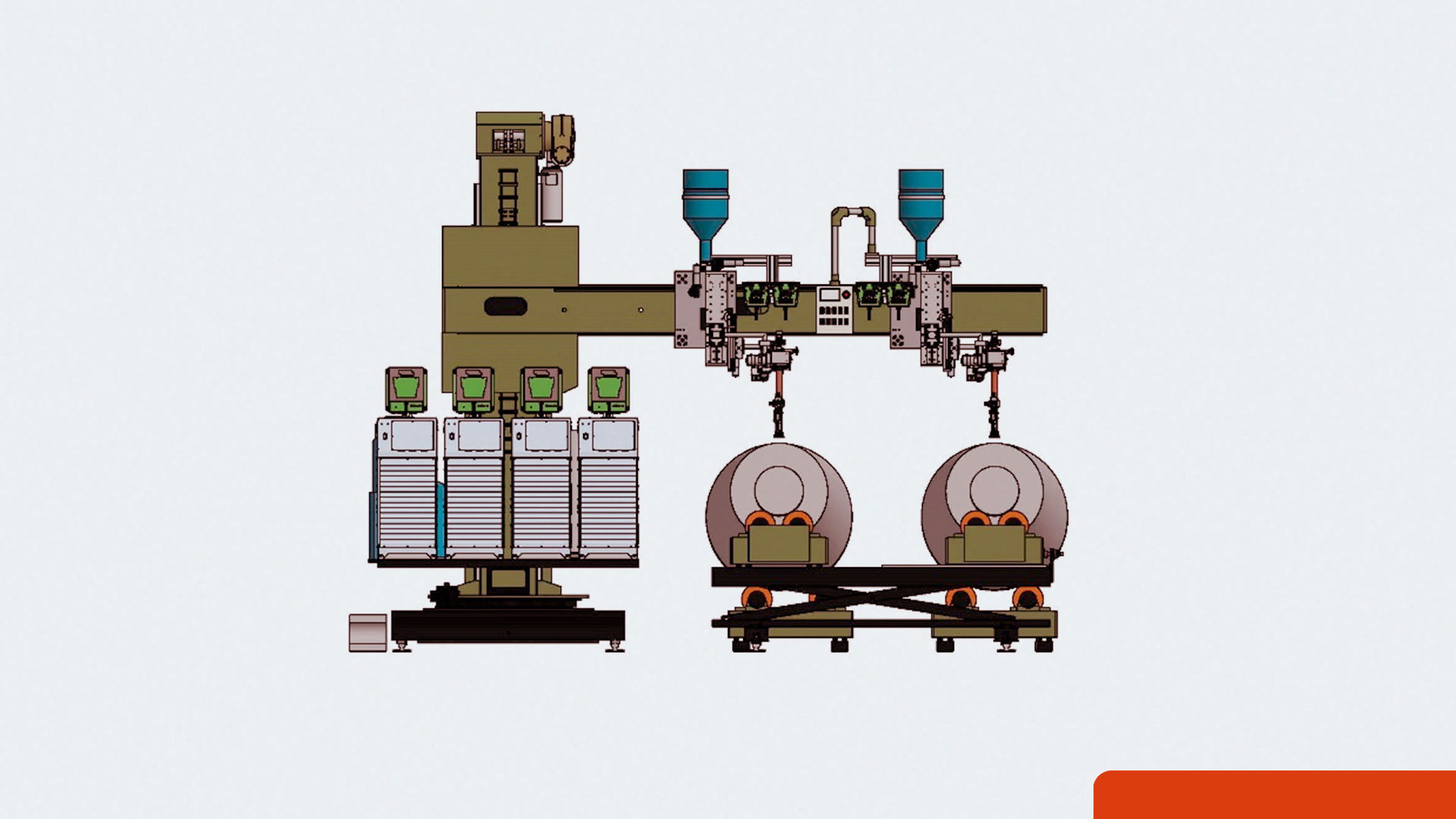

• Installation flexibility

Customers can choose, according to their needs, between a pulp outlet under the press (standard solution) or, as an alternative, on the side of the press by means of a screw conveyor placed inside the press in the outlet area.

• Increased performance

It has been obtained by increasing the size of the press and of the spindles/flights. Moreover, following the good results obtained with horizontal presses, we have considered the possibility of installing special lipped plates in the feeding chute to improve the draining of water.

The press will operate at Suedzucker’s Groß Gerau sugar factory during the 2003 campaign. Obviously we will be very pleased to supply more detailed information to anybody who may be interested in it.